Electrophoresis setups are like Tupperware. You can never find the right lid when you need it, and someone always seems to be borrowing the doohicky you need.

Here in the Eisen Lab, it turns out we've been using Marc Facciotti's electrophoresis stuff for years. He keeps his stuff organized, and, well... that's not been our strong suit lately. John, our lab manager, has been gently but inexorably herding us towards a semblance of respectability in our lab behavior. As part of this, he decided that it was time for us to get our electrophoresis stuff straightened out. So, he ordered a bunch nice of gel combs from one of our suppliers. They cost $51 each (see the "12 tooth double-sided comb", catalog number 669-B2-12, for the exact one pictured below). We bought six of them with different sizes and spacing, for a total exceeding $300.

While I appreciate that companies need to make money, this is a ridiculous price for a lousy little scrap of plastic. $300 for a couple of gel combs is cartel pricing, not market pricing. Fortunately, we happen to have a very nice 3D printer. It is very good at making little scraps of plastic. So, I busted out the calipers and tossed together some models of gel combs in OpenSCAD. A few minutes of printing later, and the $51 gel combs are heading back to the store.

Here's the code for the six well 1.5mm by 9mm comb :

f=0.01;

difference(){

difference(){

union(){

cube( [ 80, 27, 3 ] );

translate( [ 5.25, 14.3, f ] ) cube( [ 68, 9.3, 7.25 ] );

}

for ( i = [ 0:5 ] ) {

translate( [ 17.1+i*11.0, -f, -f ] ) cube( [ 1.75, 12, 5 ] );

}

}

union(){

translate( [ -f, -f, -f ] ) cube( [ 7, 12, 7] );

translate( [ 73+f, -f, -f ] ) cube( [ 7, 12, 7] );

translate( [ 0, -f, 1.6] ) cube( [ 80, 12, 8] );

}

}

Pretty easy to grasp, even if you've never seen SCAD before.

So, how much did this cost?

I ordered this plastic from ProtoParadigm at $42 for a kilogram. That's about four pennies a gram. Each of these gel combs cost about 21 cents to print. That's 1/243rd the price.

The 3D printer cost €1194.00 ($1524.62), which is less than the laptop I use for most of my work. The savings on just these gel combs has recuperated 18% of the cost of the printer.

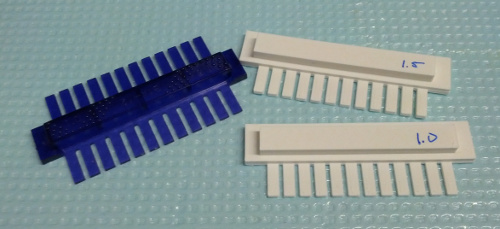

It's also important that I was able to make some minor improvements to the design. The printed combs fit into the gel mold a bit better than the "official" ones. I also made separate combs for the 1.0mm and 1.5mm versions, and the labels are easier to read. If I wanted, tiny tweaks to my SCAD file would let me make all sorts of fun combinations of thicknesses and widths that aren't available from the manufacturer. So, these gel combs are not only \(\frac{1}{243}\)'rd the price, but they are also better.

If you read the media hype about 3D printing, you will undoubtedly encounter a lot of fantastical-sounding speculation about how consumers will someday be able to print living goldfish, or computers, or bicycles. Maybe so. Maybe not. However, right now, you can print basic lab supplies and save a pile of money.

Buy your lab manager a little FDM printer and hook them up with some basic CAD training. Yes, the printer will probably mostly get used to make bottle openers and Tardis cookie cutters. So what? Your paper-printer, if you will excuse the retronym, mostly gets used for non-essential stuff too. I'd wager that for every important document printed in your lab, a hundred sheets have gone to Far Side cartoons and humorous notices taped up in the bathroom. It's a negligible expense compared to the benefits of having a machine that spits out documents when you really need them, and the social value of those the Far Side cartoons probably sums to a net positive anyway.

Conclusion : If you have a lab, and you don't have a 3D printer, you are wasting your money. Seriously.

In the time it took write this post, I printed $150 worth of gel combs, and it cost less than a cup of coffee.

Updates : Here is the tweet I originally posted about this article, before the URL for it vanishes into Twitter's memory hole. Here's an encouraging post from the Genome Web blog, and a nice article by Tim Dean at Australian Life Scientist. My article here seems to have spawned a thread on BioStar. Also, it made Ed Yong's Missing Links for November 24 over at Discover, and Megan Treacy did a really spiffy article over at Treehugger.

Many people have asked, and so I decided to see how well these kinds of 3D printed parts do in the autoclave. I tried it out with a couple of bad prints, and they seemed to hold up just fine after one or two cycles. Very thin parts did warp a bit, though, so I recommend printing parts you plan to autoclave nice and solid. Here is a before and after of a single-wall part (less than half a millimeter thick). I was expecting a puddle.